In May 2023, our commitment to environmentally conscious and climate-friendly management will be further deepened: after the environmental management certification in 2015, Werner Schmid also achieves certification of the energy management system according to the international standard ISO 50.001 in 2023.

The long history of Werner Schmid

Originally founded in 1946 by Werner Schmid as a one-man company to get a foothold in the region, and to make door and window fittings from the wreckage, Werner Schmid GmbH quickly evolved into an economically profitable company, which expanded its manufacturing range simultaneously with the economic growth in Germany, and ultimately specialised in the production of high-quality technical metal and plastic components that had stringent requirements for tolerances and complex geometries. A constantly increasing demand and the concomitant increasing number of employees have enabled Werner Schmid GmbH to keep growing till today. Regular investments in the expansion of production shops and manufacturing plants reflect the modernity of the company.

First certification of our energy management system

75 years of Werner Schmid – anniversary celebration wins multiple awards

Right in the middle of the Coronavirus pandemic, Werner Schmid celebrates it’s 75th anniversary. Due to contact limitations, a big celebration event is not possible. Therefore, Werner Schmid celebrates with a yearlong anniversary campaign for it’s employees. This unique internal campaign is awarded four prestigious awards: The German Agency Award, a Gold Stevie Award (category “Best Event for internal Appreciation and Motivation”), the German Brand Award (category „Excellence in Brand Strategy and Creation – Branded Activities During Covid 19“) and the Best Employer Brand Award 2021/22 in silver (category “Hidden Champion”)

Werner Schmid wins the Grand Prix of Medium Sized Companies

“Germanys most coveted company award” (according to newspaper DIE WELT) has been offered for more than 25 years by Leipzig-based Oskar Patzelt Foundation. Since 2003, the award is conferred Germany-wide in 12 regions. In 2019, 5.399 companies were nominated, 307 of which in the region of Hessen. Of these 307 companies, an independent jury chose 6 finalist and 3 winners – Werner Schmid being among the winners.

Long-term securing of location

Werner Schmid GmbH acquires a neighbouring plot of land with a total area of 10,000 square metres, thus ensuring continued long-term growth at the current location.

First certification of our environmental management according to ISO 14001

Being a traditional family company, Werner Schmid has long put a focus on a responsible and therefore also on an environmentally conscious manner of conducting business. To show this commitment, Werner Schmid has achieved certification of the environmental management system according to the international standard ISO 14001 in 2015.

Matthias and Joachim Hauss take over management of the company

The grandchildren of the founder of the company, Matthias and Joachim Hauss take over its management from their mother Monika Hauss-Schmid.

Expansion and acquisition of the logistics centre

As Werner Schmid GmbH once again reaches the limits of its capacity, the company again expands its headquarters and in 2010, acquires the logistics centre, with an area of more than 5,000 square metres, in the immediate vicinity of the Weichselstrasse site.

First certification according to DIN ISO/TS 16949

ISO/TS 16949 is a further development of the quality management standard ISO 9001 for the automobile industry. In 2005, Werner Schmid GmbH is certified for the first time according to this standard of the International Automotive Task Force (IATF). Since the first ISO 9001 certification in 1999, our quality management has always been certified according to this standard.

Death of the founder of the company

In awareness of having passed on his life’s work to his family, the company’s founder Werner Schmid dies at the age of 83.

Founding partner of Perspektiva

Right from the time of its founding in 1999, Werner Schmid GmbH has been involved in the non-profit initiative Perspektiva GmbH, which has set itself the goal of qualifying physically, mentally or emotionally disadvantaged young people for the primary job market.

WS gets its DIN EN ISO 9001 certification for the first time.

High quality standards have long been a matter of course for Werner Schmid. As early as in 1999, the quality management of Werner Schmid was certified according to DIN EN ISO 9001 for the first time.

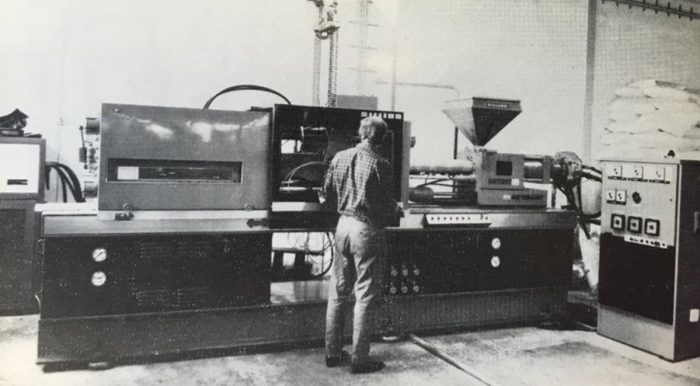

Commissioning of the automation system in the plastics production

In 1998, industrial robots arrive in manufacturing: A rotary table is linked to two injection moulding machines for the production of a reflector for a German medium-sized car.

Monika Hauss-Schmid takes over the management

The daughter of the company founder, Monika Hauss-Schmid, becomes managing director of Werner Schmid GmbH having sole power of representation.

Progressive automation of the metal parts manufacturing

What started in 1971 with automatic process step batching culminated between 1980 and 1990 in a complete conversion to automated systems with automatic belt feeding. The first hydraulic press with a table length of more than 2000 mm is commissioned at the beginning of the 1990s and gives the company a clear technological lead. Thanks to the size of the machine and the innovative tool technology, Werner Schmid is able to stamp the bayonet of a housing in the transfer tool for the first time, making it a pioneer for other companies in the industry.

Start of digitisation in toolmaking and design

Whereas so far, design work was carried out on the drawing board, from 1981, with the introduction of the first 2-D program, the company starts to rely more heavily on computer-aided systems. Digitisation arrives in the toolmaking facility of Werner Schmid with the procurement of the first CNC wire erosion machine. The entry into freely programmable control technology follows in 1986 with the deployment of the first CNC-capable milling machine.

The first metal-plastic hybrid composites

Inserts from the in-house metal part manufacturing facility are coated with plastic for the first time at the start of the eighties. Even today, the combination of the two production domains, metal and plastic, into metal-plastic hybrids remains a successful specialisation.

Automatic process step batching in metal part manufacturing

To improve its in-house manufacturing processes, in 1971, Werner Schmid GmbH expands its production facility with a mechanical as well as a hydraulic press with rail transfer. This expansion makes automatic process step batching possible.

Founding of the plastic parts manufacturing facility

In 1970, Werner Schmid GmbH is able to expand its range and develops the plastic parts manufacturing facility with an important customer. The foundation stone is laid for the core competences that continue to serve the company even today: Precision parts of metal and plastic, which are manufactured using specially designed and manufactured tools. Moreover, this rare combination of metal and plastics manufacturing integrated in one factory enables Werner Schmid to specialise in metal-plastic hybrids.

The first rebuilding for expansion of 21 till today

The site in the Weichselstrasse in Fulda in 1963 turns out to be a good choice, and enables Werner Schmid GmbH to take care of continuous growth. Thus, just four years after relocation, the first of hitherto 21 renovations for expansion can be started.

A second relocation to the current registered address

Ten years later, Werner Schmid GmbH again reaches the limits of its capacity, and in a logistical tour de force, moves into the location in the Weichselstrasse in Fulda between Christmas and New Year. This is where the company is still located, and there is sufficient space for further growth.

First change of location and conversion into a stamping plant

Continuous growth makes the first relocation necessary in 1953. At the bigger location, the company ultimately evolves into a stamping plant and starts building its first toolmaking shop. Instead of building hardware, manufacturing of stampings, pressings and drawn parts in individual operations on manually operated machines for various industrial sectors is started here.

First worker is employed

Just a year after the founding of the company, Werner Schmid employs his first worker – a young man whom he trains to become a toolmaker. This worker remains loyal to the company from the time of his training, later becomes the manager of the mechanical maintenance department and finally retires from Werner Schmid as the works manager.

Founding of Werner Schmid GmbH

The founder of the company, Werner Schmid, is a Russian prisoner of war. The young man escapes and makes his way to Fulda. Owing to a lack of contacts, financial means and the necessities of daily life, in May 1946, he starts repairing destroyed homes. That very October, he commissions his first machine and starts manufacturing furniture hardware, frame parts, door and window fittings and ashtrays from material that he picks up in scrapyards.