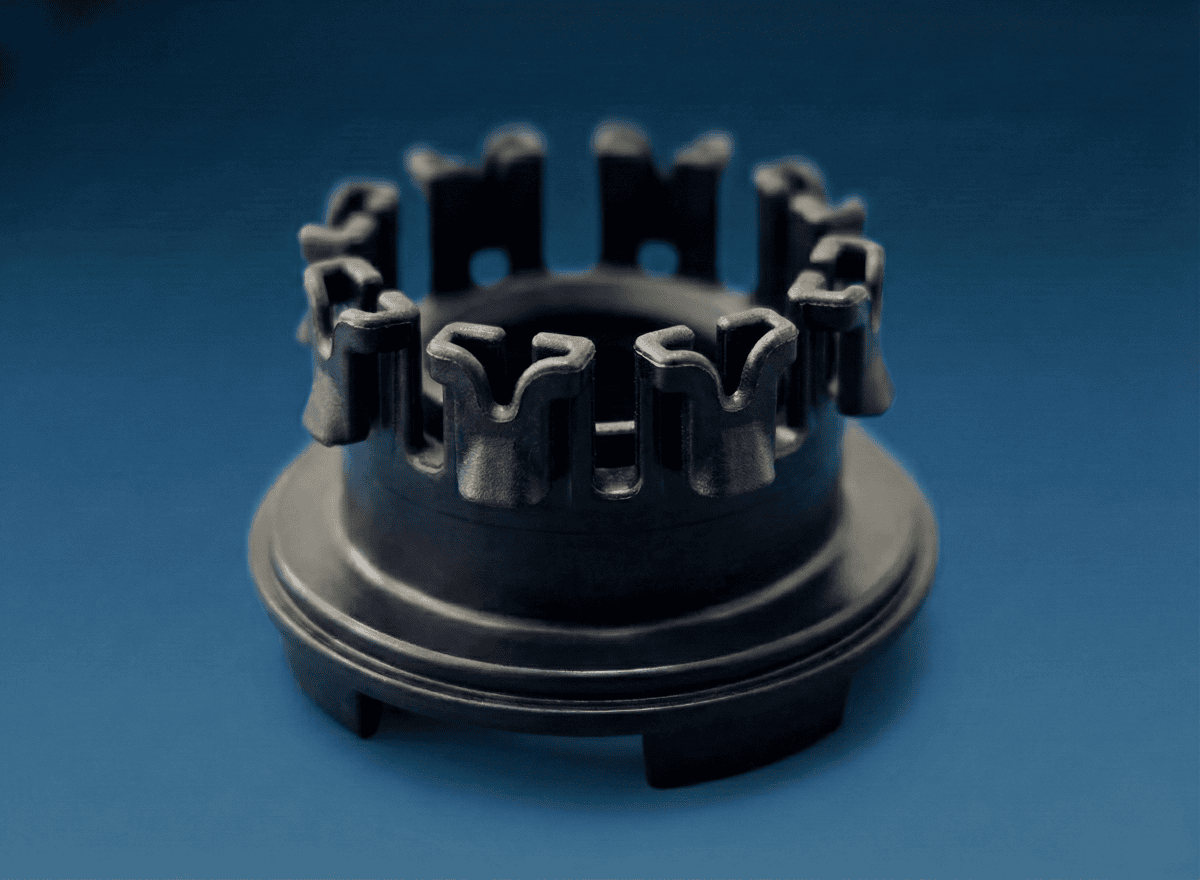

Plastic Injection Molded Parts

Your Certified Manufacturer of Technical Plastic Components

Experience meets precision engineering: As a family-owned company based in Germany with decades of tradition, we combine genuine Made in Germany quality with state-of-the-art plastic injection molding technology. We manufacture complex technical plastic components for the automotive industry as well as robust housings for mechanical engineering applications. Your CAD design is reliably transferred into stable series production.

Our injection molding expertise ensures that every component meets the highest standards of dimensional accuracy, cost efficiency, and mechanical strength—even for demanding geometries.

Request your precision plastic injection molded Parts →

Toolmaking and Plastic Injection Molding – Complete Solutions from a Single Source

Our strength lies in the combination of a modern machine park, an experienced team, and in-house toolmaking. This results in a fully integrated process that makes your projects faster, more precise, and more flexible.

Our system advantages:

In-house toolmaking:

- We design and manufacture injection molding tools in-house—short communication paths, fast response times, and precise adjustments throughout the project phase.

Modern injection molding machines:

- Appropriately sized clamping forces and automated processes ensure stable production and consistently high-quality parts.

Certified quality:

- Our processes comply with IATF 16949—a quality standard especially trusted by customers in the automotive and electrical industries.

Our Capabilities in Precision Plastic Injection Molding

We manufacture plastic components precisely to your requirements—from functional parts to high-performance components. Using precision plastic injection molding, we produce dimensionally accurate parts with minimal tolerances, even for complex assemblies and safety-critical applications.

Our materials:

We process a wide range of high-performance plastics, including reinforced polyamides (PA), polyacetals (POM), and PC/ABS blends.

Whether high-volume production, small series, or prototyping—our manufacturing, volumes, and time-to-market are tailored precisely to your needs. With just-in-time deliveries and customer-specific packaging, your components are delivered directly to your production line—reliable, on schedule, and ready for use.

Industries and Applications for Plastic Injection Molded Parts

Our plastic molded parts are used across a wide range of technology-driven industries. They stand out for precision, cost efficiency, and high process reliability.

Typical application areas for our plastic components include:

- Automotive industry – e.g. connectors, clips, instrument cluster components, and functional parts for interior and engine compartment applications.

- Electronics – electronic housings, insulating parts, coil formers, and carrier plates.

- Mechanical engineering – gears, bearings, covers, and technical functional components.

- Ventilation and air-conditioning technology – flow-optimized molded parts, valve components, and structural elements.

- Measurement and control technology – housings, carrier elements, sealing components, and functional carriers.

Your Project Partner for Plastic Injection Molded Components

Whether low-volume injection molding, technical plastic components for the automotive industry, or complex housings manufactured to drawing—we support you from development and toolmaking through to series production.

➡️ Send us your specification. We guarantee a fast and well-founded response to your project.